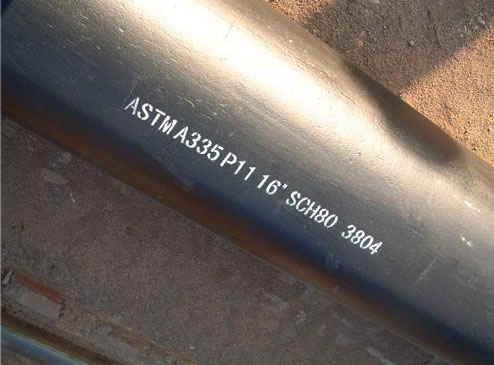

ASTM A335 P11 Seamless Ferritic Alloy-Steel Pipe for High-Temperature Service.

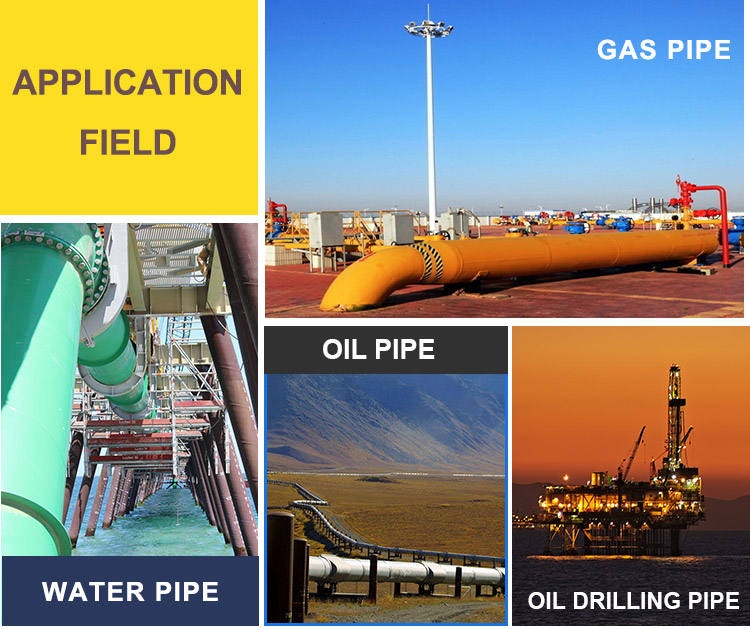

The main purpose of alloy steel pipe is to use in power plants, nuclear power, high-pressure boilers, high-temperature superheaters and reheaters and other high-pressure and high-temperature pipelines and equipment. It is made of high-quality carbon steel, alloy structural steel and stainless heat-resistant steel. , After hot rolling (extrusion, expansion) or cold rolling (drawing). Alloy steel pipe is a kind of seamless steel pipe, its performance is much higher than the general seamless steel pipe, because this steel pipe inside containing Cr, high temperature resistance, low temperature, corrosion-resistant performance of other non-pipe joints not match, so the more extensive use of alloy tube in the petroleum, aerospace, chemical, electric power, boiler, military, and other industries.

ASTM A335 standard is issued under the fixed designation A 335/A 335M; the number immediately following the designation indicates the year of original adoption or, in the case of revision, the year of last revision.

The most common use of grades P11, P22, and P91 is in the power industry and petro-chemical plants, Grades P5 and P9 are commonly used in refineries.

ASTM A335 is often called as chrome moly pipe because of the chemical contain of Molybdenum (Mo) and Chromium (Cr). Molybdenum increases the strength of steel and Chromium (or chrome) is the essential constituent of stainless steel.

The composition chrome moly alloy steel pipe make it ideal for use in power plants, refineries, petro chemical plants, and oil field services where fluids and gases are transported at extremely high temperatures and pressures.

Chrome moly pipe under ASTM & ASME specification A/SA 335 P1, P2, P11, P12, P15, P22, P91, P92, P122 are used for power industries whereas ASTM/ASME A/SA 335 P5, P9 are used for petrochemical industries

Strong resistance to rupturing at high temperatures and high pressures

May be used for Hydrogen Sulfide Corrosion Services

Resistant to cracking from hydrogen attack and embrittlement

Resistant to hot sulfide corrosion cracking

Can be used for NACE Applications where sour environments are under high temp and pressure

Can be used in NACE-MRO 175 Sour Service

Ideal for creep rupture applications

Can handle high temperatures with very low elasticity

Certitifcation: Chrome Moly pipe are certified as PER DIN 50049 3.1, EN 10204 3.1/3.2 and NACE MR-0175 & NACE MR-0103

| Product Name | ASTM A335 Seamless Ferritic Alloy Steel Pipe for High-Temperature Service |

| Standard | ASTM A335 |

| Grades | P1, P2, P5, P9, P11, P12, P15, P22, P91, P92, P122 |

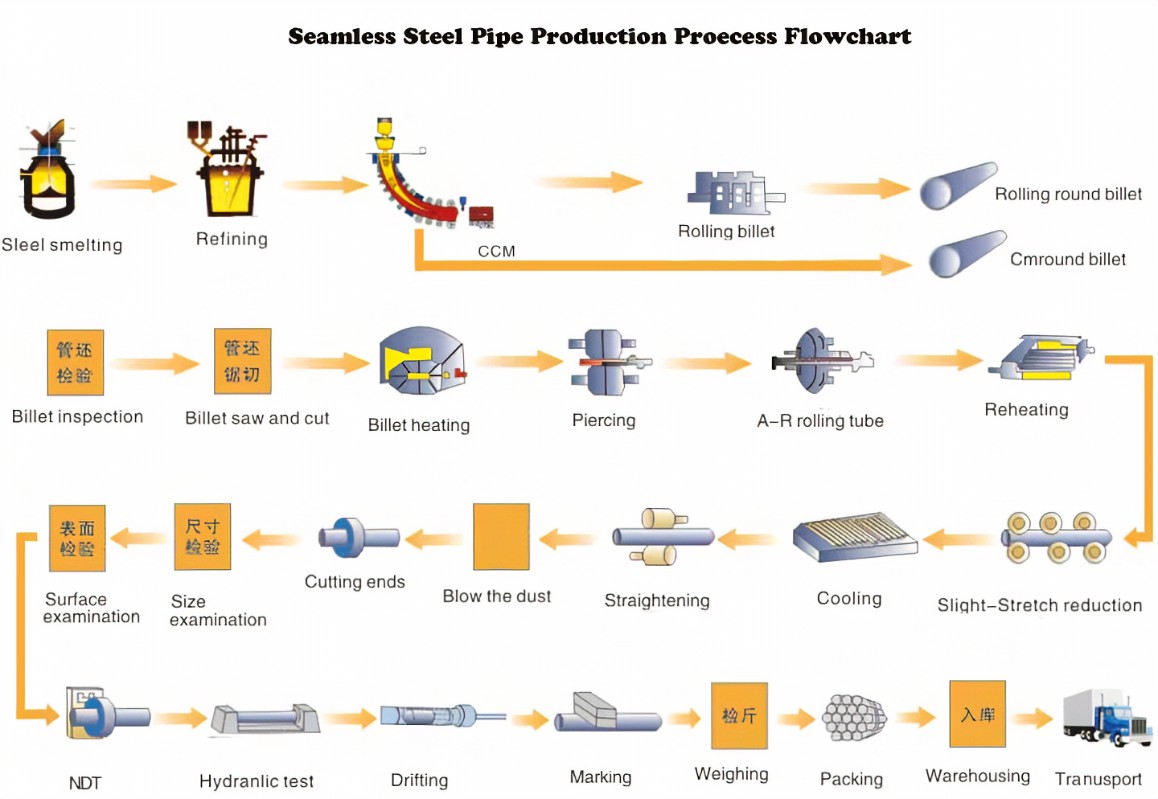

| Production Process | Hot Rolled,Cold Rolled ,Cold Drawn |

| Tolerance | OD :+/-1% ,WT:+/-1% ,Length:+/-5cm |

| Length | 3-12m or as per customers' requirements |

| Surface | According to customer Requirement |

| Payment Terms | EXW, FOB, CIF, CFR etc. |

| Trade Terms | TT, LC,OA,DP etc. |

| Delivery Time | Within 14 days after Receiving 30% TT Advanced or LC at Sight Original |

| Application | Alloy steel pipes are mainly used for high-pressure and high-temperature pipelines and equipment such as power plants, nuclear power, high-pressure boilers, high-temperature superheaters and reheaters. They are made of high-quality carbon steel, alloy structural steel and stainless heat-resistant steel. , by hot rolling (extrusion, expansion) or cold rolling (drawing). |

Chemical composition table

These pipe bear high resistance to rupture at high temperature and pressures. With hydrogen crack resistance and sulfide stress corrosion cracking chrome moly pipe are highly preferred over Carbon pipe.

| Grade | UN Sequiv. | C≤ | Mn | P≤ | S≤ | Si≤ | Cr | Mo |

|---|---|---|---|---|---|---|---|---|

| P1 | K11522 | 0.10~0.20 | 0.30~0.80 | 0.025 | 0.025 | 0.10~0.50 | – | 0.44~0.65 |

| P2 | K11547 | 0.10~0.20 | 0.30~0.61 | 0.025 | 0.025 | 0.10~0.30 | 0.50~0.81 | 0.44~0.65 |

| P5 | K41545 | 0.15 | 0.30~0.60 | 0.025 | 0.025 | 0.5 | 4.00~6.00 | 0.44~0.65 |

| P5b | K51545 | 0.15 | 0.30~0.60 | 0.025 | 0.025 | 1.00~2.00 | 4.00~6.00 | 0.44~0.65 |

| P5c | K41245 | 0.12 | 0.30~0.60 | 0.025 | 0.025 | 0.5 | 4.00~6.00 | 0.44~0.65 |

| P9 | S50400 | 0.15 | 0.30~0.60 | 0.025 | 0.025 | 0.50~1.00 | 8.00~10.00 | 0.44~0.65 |

| P11 | K11597 | 0.05~0.15 | 0.30~0.61 | 0.025 | 0.025 | 0.50~1.00 | 1.00~1.50 | 0.44~0.65 |

| P12 | K11562 | 0.05~0.15 | 0.30~0.60 | 0.025 | 0.025 | 0.5 | 0.80~1.25 | 0.44~0.65 |

| P15 | K11578 | 0.05~0.15 | 0.30~0.60 | 0.025 | 0.025 | 1.15~1.65 | – | 0.44~0.65 |

| P21 | K31545 | 0.05~0.15 | 0.30~0.60 | 0.025 | 0.025 | 0.5 | 2.65~3.35 | 0.80~1.60 |

| P22 | K21590 | 0.05~0.15 | 0.30~0.60 | 0.025 | 0.025 | 0.5 | 1.90~2.60 | 0.87~1.13 |

| P91 | K91560 | 0.08~0.12 | 0.30~0.60 | 0.02 | 0.01 | 0.20~0.50 | 8.00~9.50 | 0.85~1.05 |

| P92 | K92460 | 0.07~0.13 | 0.30~0.60 | 0.02 | 0.01 | 0.5 | 8.50~9.50 | 0.30~0.60 |

production process